How to Install Our PVC Gates

If you’ve ever had a wooden gate, then you know — they can be a pain. Unlike a door protected by an overhang, gates are fully exposed to the elements. You’ve hardly had time to admire your beautiful new gate before it needs to be re-painted or re-stained. And then you do it again. And again. Before long, the wood starts to rot, the gate begins to sag and stick, and you’re trapped in an endless cycle of sanding, painting, and rehanging — until you finally find yourself Googling “low-maintenance gates.” And perhaps that’s what brought you here!

Or maybe you’ve been on board the low-maintenance material trend for a while. Either way, welcome! We started manufacturing solid PVC gates for this very reason. These gates will never rot or decay and don’t need to be painted (though if you want to, they hold paint much better than wood — just be sure to read our painting instructions here).

Because our gates are cut on our CNC machine right here at our shop in Nashville, TN, the design options are virtually endless.

So, if you’ve made it this far, you’re likely already sold on PVC gates — and now you’re trying to figure out how to actually hang them!

We don’t have step-by-step written instructions for gates like we do for some of our other product lines (such as our railing panels). That’s because every installation is a little different and requires a slightly different approach. So let’s walk through a few of the most common scenarios.

Setting Your Structural Posts

Before anything else, you’ll need to get your structural posts set.

For our larger laminated gates, we recommend having your installer set structural 6×6 posts at least 30″ into the ground. For our smaller flat sheet gates, posts set about 18″ deep may be sufficient.

Keep in mind — the taller or heavier the gate, the more torque is applied when it’s open.

If you’re installing smaller flat sheet gates on an existing deck and don’t have posts, a post anchor such as the Titan Post Anchor or the Timbertech Secure-Mount Posts could be a great solution.

Either way, your posts should be plumb and spaced so there’s a ½″ gap on either side of the gate. In other words, if you’re purchasing a 42″ wide gate, your finished posts (accounting for any sleeve or wrap) should be 43″ apart. For double gates, also include a ½″ gap between the two gates.

There are many ways to set or anchor posts, so your installer will need to determine what works best for your situation.

Planning for Hardware and Placement

The next step before installing your gates is to plan for your hardware and hardware placement.

For small flat sheet single gates, use two hinges on one side and a latch on the other.

For small flat sheet double gates, you’ll need four hinges (two per gate), one latch, and one cane bolt.

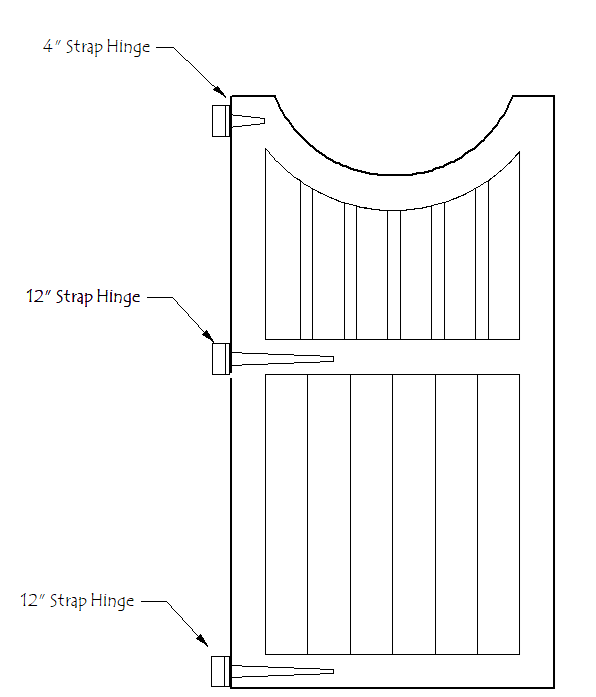

For larger laminated gates, we recommend using two to three hinges per gate.

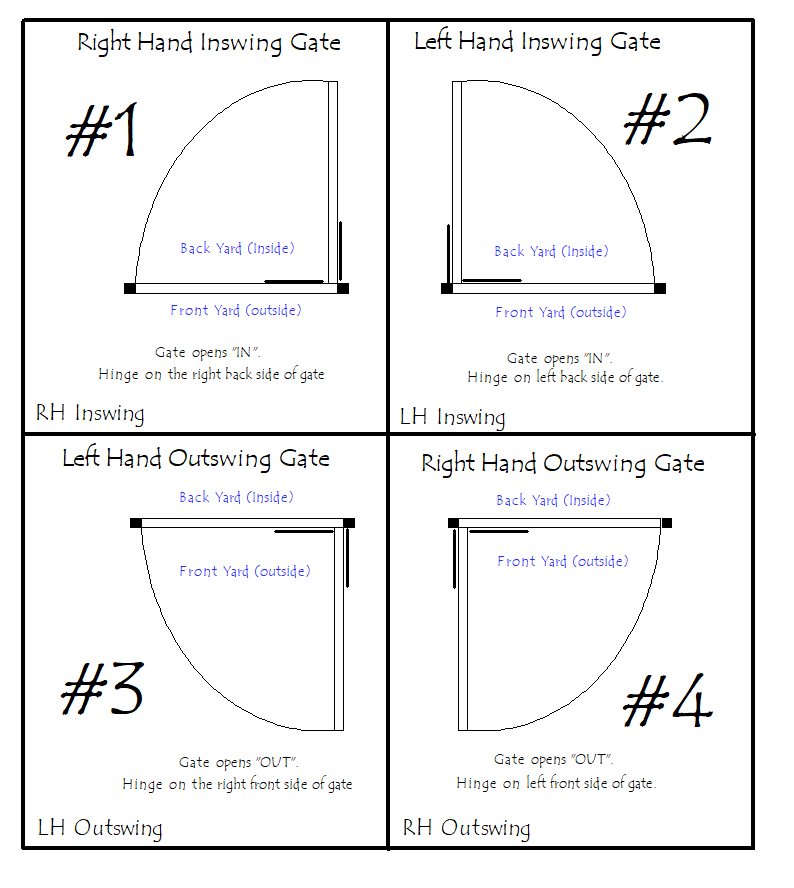

You’ll want to install your hinges so that the gate swings the way you prefer — inswing or outswing.

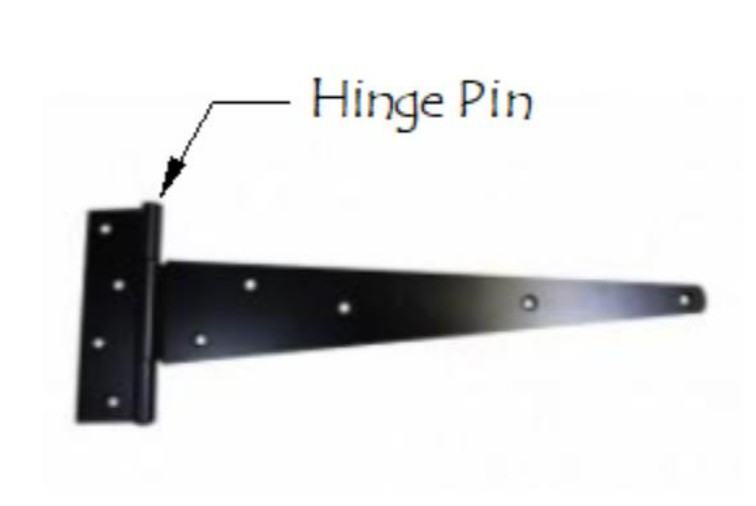

Selecting the right hinges is key to a well-functioning gate — and with our PVC gates, it’s especially important to get it right. We recommend using strap hinges (hinges with through bolts would be strongest) at both the top and bottom of the gate. A strap hinge runs across the face of the gate, helping to distribute the load evenly and prevent warping. The longer the strap, the better.

Selecting the right hinges is key to a well-functioning gate — and with our PVC gates, it’s especially important to get it right. We recommend using strap hinges (hinges with through bolts would be strongest) at both the top and bottom of the gate. A strap hinge runs across the face of the gate, helping to distribute the load evenly and prevent warping. The longer the strap, the better.

For gates taller than four feet, consider using three hinges, and make sure the length of each strap is at least one-third the width of the gate. Depending on your design, you may need to use a shorter strap hinge at the top; what matters most is that all hinge pins are the same diameter.

Recommended Gate Hardware

Our favorite brand of gate hardware is Abbey Trading.

We recommend these T-hinges for your gates:

For latches, we love these options:

Application #1: Installing PVC Gates with Wooden Posts

Once you have your hardware selected and your swing direction decided, attach your hinges to your posts and gates accordingly. Maintain a ½″ gap between your posts and gates, as well as between double gates.

Attach your latch to the opposite side, and for double gates, install a cane bolt at the bottom of one gate.

Application #2: Installing PVC Gates with Brick or Stone Columns

If you’re attaching gates to brick or stone columns, you likely don’t have a flush surface. In that case, we recommend using metal jambs.

Purchase hollow 2×2 metal jambs from your local supplier, fill them with wood (so your screws have something to bite into), and bolt them to the center of your columns so they’re plumb. Maintain a ½″ gap between your jamb and your gate.

You can then attach the same hinges and latches mentioned above directly to the metal jambs, keeping in mind your desired swing direction.

You may even choose to use this jamb method with wooden posts if you prefer your gate to sit in the center of your posts rather than flush with the front or back.

Other Installation Scenarios

There are countless possible scenarios for gate installations, so it’s impossible to cover them all here. Ultimately, it’s up to you and your installer to determine the best approach for your setup.

-

This customer installed a jamb on one side only and attached the gate directly to a wooden column on the other.

-

This customer used one of our half sleeves on one side and a full sleeve on the other.

-

This customer chose crank band hinges instead of tee hinges, allowing installation on the inside of the post rather than the face.

We hope that however you install your Porch Store PVC Gates, you enjoy them for many, many years to come.

Have questions? Call or e-mail us : 615-730-8067 | info@porchstore.com